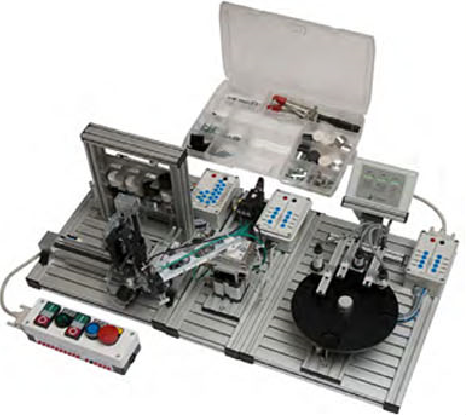

Multilevel Storage System with Pieces Identification Station on Rotary Indexing Table in Closed Loop Mode

Categories: Automation TechnologiesThe mechatronic system consists of the following elements:• Cartesian control storage module• Pneumatic arm module • Rotary indexing table module • Pushbutton panel• Touchscreen operator pan...

Product

Description

The mechatronic system consists of the following elements:

• Cartesian control storage module

• Pneumatic arm module

• Rotary indexing table module

• Pushbutton panel

• Touchscreen operator panel

• Box of tools and workpieces

Description of the cycle:

Starting from the three-level storage module in which the work pieces are arranged in a jumbled fashion, the working cycle, totally controlled by PLC, consists of:

• Withdrawing the piece from the storage module

• Transporting the piece to the Pieces Identification Module by means of the Pick-and-Place module

• Identification of the material/color of the piece by means of a set of sensors.

• The display of the identification result

• Removing the piece from the Rotary Indexing Table after identification.

• Positioning the piece in the respective cell of the Cartesian Storage module

A PLC (not included) is required for controlling the process and must have at least:

• 20 digital inputs 24 VDC

• 13 digital outputs 24 VDC, 0.5 A

Suggested PLC:

2 PLC trainers interconnected via PROFINET industrial network. Connection to the modules is carried out via 2 mm sockets.

Alternative:

• 1 PLC trainer with programming and simulation software. Connection to the modules is carried out via 2 mm sockets.

quick overview :

The mechatronic system consists of the following elements:

• Cartesian control storage module

• Pneumatic arm module

• Rotary indexing table module

• Pushbutton panel

• Touchscreen operator panel

• Box of tools and workpieces

Description of the cycle:

Starting from the three-level storage module in which the work pieces are arranged in a jumbled fashion, the working cycle, totally controlled by PLC, consists of:

• Withdrawing the piece from the storage module

• Transporting the piece to the Pieces Identification Module by means of the Pick-and-Place module

• Identification of the material/color of the piece by means of a set of sensors.

• The display of the identification result

• Removing the piece from the Rotary Indexing Table after identification.

• Positioning the piece in the respective cell of the Cartesian Storage module

A PLC (not included) is required for controlling the process and must have at least:

• 20 digital inputs 24 VDC

• 13 digital outputs 24 VDC, 0.5 A

Suggested PLC:

2 PLC trainers interconnected via PROFINET industrial network. Connection to the modules is carried out via 2 mm sockets.

Alternative:

• 1 PLC trainer with programming and simulation software. Connection to the modules is carried out via 2 mm sockets.

Product

Reviews

add Review

reviews

No Review Yet.

Copyrights © 2025 All Rights Reserved by Atico

Product

Reviews

add Review

reviews

No Review Yet.