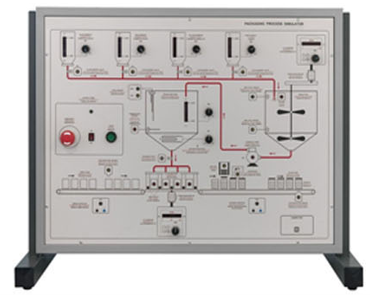

Packaging Process Simulator

Categories: Automation TechnologiesThe simulator has been designed and carried out for the complete study of a bottling process of liquids into cylindrical containers and next packaging process with final quality control (QC).It is com...

Product

Description

The simulator has been designed and carried out for the complete study of a bottling process of liquids into cylindrical containers and next packaging process with final quality control (QC).

It is composed of:

• A panel reporting the color silk screen diagram of a real industrial plant

• Multimedia graphical software enabling, via PC simulator connection:

- the control and supervision of the system;

- the consultation of theoretical hypertexts and digitized images.

The center of the simulator consists of the automated machine filling the empty containers with mixed and properly dosed liquid substances. The simulator reproduces all functions and conditions of the packaging plant enabling the analysis of many technological subjects such as:

• Automated dosing systems

• Motion

• Automated filling machines

• Computerized weighting systems

• Packaging systems

• Safety in the packaging systems

The presence on the panel of many potentiometers, pushbuttons, switches, LED diodes and graphic bars enables to easily manipulate the values of the process variables. These actions can be carried out from PC, too, with the help of the interactive software enabling at the same time the real time report of the process state by means of dynamic graphical objects. At last, the theoretical study, the exercises and the use of the simulator are effectively guided by a complete theoretical/practical set of handbooks provided with the

equipment.

TRAINING PROGRAM:

The simulator enables the study of the following main subjects:

• Industrial packaging plants

• Automated dosing of liquid and solid substances

• Mixers of liquid substances

• Inner motion systems

• Structure and automation of a filling machine

• Logistics

• Safeties on the packaging plants

• Emergency and alarms

• Monitoring and control of the iron process via PC

TECHNICAL SPECIFICATIONS:

• Sheet steel structure, chemically treated and painted with epoxy paint

• Colored silk-screen panel representing the plant

• Setting and manipulation of the process variables via:

- Potentiometers

- Pushbuttons

- Switches

• Visualization of the process variables via:

- LED diodes

- Bargraph

• Electronic card for control of the digital and analog I/O on the simulator provided with USB interface for communication with PC

• USB cable for simulator/PC communication

• Power Supply: 230 Vac 50 Hz single-phase - 50 VA (Other voltage and frequency on request)

quick overview :

The simulator has been designed and carried out for the complete study of a bottling process of liquids into cylindrical containers and next packaging process with final quality control (QC).

It is composed of:

• A panel reporting the color silk screen diagram of a real industrial plant

• Multimedia graphical software enabling, via PC simulator connection:

- the control and supervision of the system;

- the consultation of theoretical hypertexts and digitized images.

The center of the simulator consists of the automated machine filling the empty containers with mixed and properly dosed liquid substances. The simulator reproduces all functions and conditions of the packaging plant enabling the analysis of many technological subjects such as:

• Automated dosing systems

• Motion

• Automated filling machines

• Computerized weighting systems

• Packaging systems

• Safety in the packaging systems

The presence on the panel of many potentiometers, pushbuttons, switches, LED diodes and graphic bars enables to easily manipulate the values of the process variables. These actions can be carried out from PC, too, with the help of the interactive software enabling at the same time the real time report of the process state by means of dynamic graphical objects. At last, the theoretical study, the exercises and the use of the simulator are effectively guided by a complete theoretical/practical set of handbooks provided with the

equipment.

TRAINING PROGRAM:

The simulator enables the study of the following main subjects:

• Industrial packaging plants

• Automated dosing of liquid and solid substances

• Mixers of liquid substances

• Inner motion systems

• Structure and automation of a filling machine

• Logistics

• Safeties on the packaging plants

• Emergency and alarms

• Monitoring and control of the iron process via PC

TECHNICAL SPECIFICATIONS:

• Sheet steel structure, chemically treated and painted with epoxy paint

• Colored silk-screen panel representing the plant

• Setting and manipulation of the process variables via:

- Potentiometers

- Pushbuttons

- Switches

• Visualization of the process variables via:

- LED diodes

- Bargraph

• Electronic card for control of the digital and analog I/O on the simulator provided with USB interface for communication with PC

• USB cable for simulator/PC communication

• Power Supply: 230 Vac 50 Hz single-phase - 50 VA (Other voltage and frequency on request)

Product

Reviews

add Review

reviews

No Review Yet.

Copyrights © 2025 All Rights Reserved by Atico

Product

Reviews

add Review

reviews

No Review Yet.