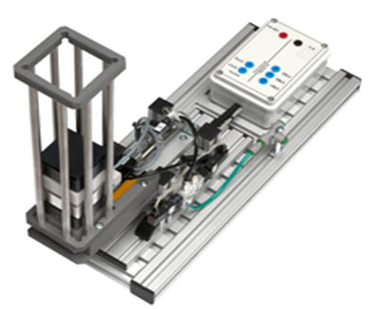

Storage Module for Prismatic Pieces

Categories: Automation TechnologiesThe module is used to distribute prismatic pieces. It has been designed to work with the module of conveyor belt. Pieces are expelled by a double-acting cylinder controlled by a 5/2-way solenoid valve...

Product

Description

The module is used to distribute prismatic pieces. It has been designed to work with the module of conveyor belt. Pieces are expelled by a double-acting cylinder controlled by a 5/2-way solenoid valve. The presence of pieces in the column is detected by a microswitch sensor, whereas the position of the cylinder is detected by two REED sensors. The complete control of the module is

carried out by a PLC (optional) linked to the system through an I/O interface box. The PLC programming software allows the development of a wide set of automation experiences with the module, working in an integrated cycle or in a stand alone mode. Finally, the module supervision is carried out with the software.

TRAINING PROGRAM:

The training program that can be developed with the module includes:

• Principles of electro-pneumatics

• Operation of microswitch sensors

• Operation of REED sensors

TECHNICAL SPECIFICATIONS:

Modular unit assembled on a aluminium section bar structure. It includes I/O interface box with:

• Ø = 2 mm terminals

• Cable with 25-pole D-SUB plug connector

Besides performing the function of control board for the module, this interface box also enables the students to carry out electrical measurements on the components of the module. The control of the module is possible through the follow PLC training panels (not supplied):

• PLC training panels: manages the module through Ø = 2 mm terminals. In case one of these two panels is used, a 24 Vdc power supply is already mounted on board.

Sensors and actuators:

• 1 Microswitch sensor

• 2 REED sensors

• 1 5/2 electro-valve

Station inputs and outputs:

• 3 Digital inputs

• 2 Digital outputs

quick overview :

The module is used to distribute prismatic pieces. It has been designed to work with the module of conveyor belt. Pieces are expelled by a double-acting cylinder controlled by a 5/2-way solenoid valve. The presence of pieces in the column is detected by a microswitch sensor, whereas the position of the cylinder is detected by two REED sensors. The complete control of the module is

carried out by a PLC (optional) linked to the system through an I/O interface box. The PLC programming software allows the development of a wide set of automation experiences with the module, working in an integrated cycle or in a stand alone mode. Finally, the module supervision is carried out with the software.

TRAINING PROGRAM:

The training program that can be developed with the module includes:

• Principles of electro-pneumatics

• Operation of microswitch sensors

• Operation of REED sensors

TECHNICAL SPECIFICATIONS:

Modular unit assembled on a aluminium section bar structure. It includes I/O interface box with:

• Ø = 2 mm terminals

• Cable with 25-pole D-SUB plug connector

Besides performing the function of control board for the module, this interface box also enables the students to carry out electrical measurements on the components of the module. The control of the module is possible through the follow PLC training panels (not supplied):

• PLC training panels: manages the module through Ø = 2 mm terminals. In case one of these two panels is used, a 24 Vdc power supply is already mounted on board.

Sensors and actuators:

• 1 Microswitch sensor

• 2 REED sensors

• 1 5/2 electro-valve

Station inputs and outputs:

• 3 Digital inputs

• 2 Digital outputs

Product

Reviews

add Review

reviews

No Review Yet.

Copyrights © 2025 All Rights Reserved by Atico

Product

Reviews

add Review

reviews

No Review Yet.